- No Obligations

- Stop Paying Too Much For Your Contractor

- No Spam Calling

- Screened & ID Checked Contractors only!

Power Tool Maintenance: Best Practices for Keeping Your Power Tools Performing Great

0

Power Tool Maintenance: Best Practices for Keeping Your Power Tools Performing Great

earlyexperts.net

Power Tool Maintenance: Best Practices for Keeping Your Power Tools Performing Great

earlyexperts.net

The essence of power tools is to serve you for as long as possible. Their life span is not a guarantee, however, and their performance may dwindle following neglect. Just like any good thing in life, you have to take proper care of the machines for them to serve you optimally. Proper maintenance translates to an increased life expectancy, and the tools will outlive the project if they are under proper maintenance. The essential aspects of maintenance include proper storage and regular servicing of the tools. These major aspects will ensure that you enjoy prime services for a long time. Here are some tips on how you can enhance the performance of your power tools.

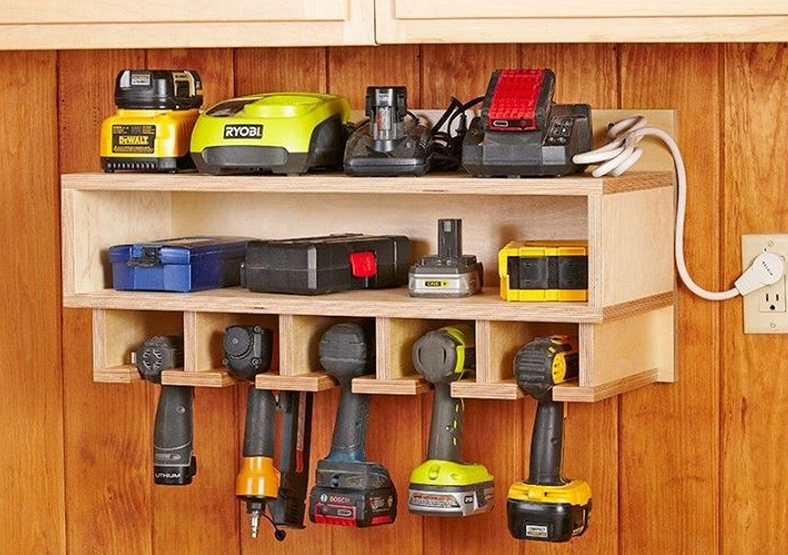

Proper Storage

The first step towards ensuring you get the best service from your tools is proper storage. Power tools will be exposed to risks such as corrosion if you expose them to elements such as water. Storing them in a protected, dry section of the house, on the other hand, ensures that the tools are not exposed to these elements. In turn, they remain in great shape and this leads to a long life expectancy. Moreover, this prevents unnecessary wear and tear. The storage space should also be clean and organized. This implies that each tool stays in its place, and this further prevents accidental damage to your tools. Moreover, good organization enhances the safety of the tools. Additionally, the storage area needs to be well ventilated. Once more, the power tools are damaged when exposed to elements, and a well-ventilated area ensures they are safe. Here, no moisture will accumulate and damage the goods. Moreover, moulds will not grow on the tools making it hard to keep them safe. This is especially the case if the tools are not in constant use. Therefore, when the tools are needed once more, then the tools will still be working optimally. Regardless of the effort needed to keep the tools well stored, this step is necessary for preventing the frustration that may arise from losing a power tool to negligence.

Proper Care and Maintenance

The next strategy that prolongs the life of a power tool is proper care and maintenance. Just storing the tools will not be enough if you do not take good care of them before storage. Moreover, the tools require constant checking to maintain their cleanliness and integrity during storage. The delicate nature of the power tools discourages rough cleaning. Therefore, the proper cleaning routine should involve the use of a soft cloth or tooth brush to clean off any loose debris that might be entangled in the casings of the power tool. The most appropriate course of action in keeping the vents of the power tool clean is by using an air compressor. The air compressor enhances the performance of a tool by increasing ventilation within the machine. This ensures the machine runs at a slower speed, and in a cooler manner that leads to a longer life.

Proper maintenance and care also involve the use of lubricants on specific parts of the power tools to reduce wear and tear due to friction. Most tools often have a guide on the proper way to lubricate the machines in their manual. Another aspect of concern in the care routine involves the joints off the power tools. Fasteners such as screws often come loose after regular use. These may be lost if they are not tightened on time. Check on the fasteners frequently to avoid loss of the screws and ensure the tools are working optimally. Replacing the worn out parts of the power tool immediately also goes a long way to ensure the tools remain in great shape. This is especially the case with electrical cords that could prove fatal is they are used while faulty. The sharp parts of the tools such as blades should also be maintained to ensure they are not worn out or damaged. Moreover, the user manual goes a long way in guiding you on how to keep the power tool in good shape through care and maintenance.

Replacing Worn out Parts

The parts making up the power tools are prone to wear and tear. This does not mean the whole machine is useless. It is like a car that required a change of brake pads while the engine is still in optimal condition. Do not write off your machine due to wear and tear of certain parts. Rather, replace the worn out parts and continue using your machine as usual. Examples of replaceable power tool parts include switch assemblies, accessories, carbon brushes, tires, power cards, and tires. Constant evaluation will guide you to ensure you realize when these parts need replacement. Prompt replacement of troublesome parts is essential in ensuring the rest of the machine is not affected. This indicates the need for regular servicing of the power tools to trouble shoot any telling signs.

In brief, a power tool is a costly acquisition that should serve you as long as possible to ensure you get a return on your investment. The tools can work in their full potential for a long period if you take good care of them and maintain their standards of operation through regular cleaning and evaluations. The need for proper storage cannot be overemphasized in this regard. Storing the tools the right way ensures they are kept away from dangerous elements such as water and moisture, and that they get enough air ventilation. Cleaning the tools using a soft cloth, toothbrush and air conditioner can also prolong the life of the machine. Moreover, replacing worn out tools such as switch assemblies, accessories, carbon brushes, tires, power cards, and tires further enhances the life of the machine. Therefore, proper care and maintenance, though hectic and wanting, will go a long way in ensuring you get the best out of your power tool, for the longest time possible. This is the essence of regular evaluation and commitment to maintenance.