Garage Flooring Cost & Contractor Quotes

Our garage flooring cost guide includes details in regard to all flooring application, paint, as well as up to 4 free contractor quotes.

Like all parts of the home the garage should have the appearance that tells you its purpose. It would be silly having a living room or bedroom carpet in the garage so it makes sense that a garage needs its own distinctive flooring to tell you what the room is for.

Uses of a garage

So what is the room for? Well the most obvious use is somewhere to store a car or two or maybe even maintain a car. A lot of garages are used as a general workshop or hobby room. Let’s just list a few of the common uses of a garage and see if we can come up with ideas of the kind of floor each activity needs.

Storing a car. This needs a strong floor able to withstand wear and tear. The most obvious choice here is concrete.

Car maintenance. Once again we need a strong and stable floor able to withstand much wear and tear. Car maintenance also tends to be very oily so we don’t want a flooring that will absorb oil or become slippery, we want a floor that we can easily mop up any spills. So the concrete floor we have already decided upon will need to be sealed in some way.

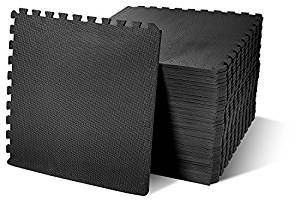

Gymnasium. A lot of people use their garage to use as a work-out room. This activity will need something on the floor that is soft yet firm. Something to absorb shocks to pounding feet and legs and to soften the floor in case of a fall. The ideal surface here would be a removable rubber mat that can be laid on the floor when needed and put away when not.

Playroom. A playroom tends to have children crawling around on the floor. For this purpose you would need something that will insulate the floor preventing the knees from becoming cold on the bare concrete. You will need something to keep the children and toys clean as well as being washable and easily cleaned. You will need something soft or at least non-abrasive to prevent scrapes and cuts in case of children falling over. Once again the temporary rubber mat would be a good idea.

Other hobbies. All other hobbies would need either the sealed concrete or the protection of a hardwearing rubber mat.

To summarise the type of flooring we would need for our garage:

A concrete floor that can be sealed to

- Prevent liquids soaking into the porous concrete

- Prevent dust from being raised from the concrete

- Prevent the concrete from chipping and becoming damaged

- Prevent slips

- Make it easy to clean up debris and dust

A temporary cover for the concrete floor that:

- Can be deployed when needed and stored easily when other activities take place

- Is strong and firm enough to allow people to walk upon it easily

- Soft enough to allow people to have skin in direct contact with it

- Soft enough to absorb impacts

- Smooth enough to provide a useful flooring surface

- Can insulate a cold concrete surface

- Impermeable to spilled liquids

- Able to withstand staining by oils and similar liquids

- Easily extended to provide just enough useful area

What flooring options are available?

Concrete

Garage floors are usually made from concrete anyway and are made when the building itself is constructed. Unfortunately, the standard of concreting skills used is often significantly lacking. This isn’t always down to lack of skill (although the garage floor is often given to a trainee to pour, and is often done by hand rather by machine), more often than not the poor quality floor is due to poor lighting when levelling the concrete, concrete that is too wet and using the place as a depository for odds and ends of bricklaying mortar at the end of the day.

The resulting mix can make for a floor that is full of hollows and bumps and sometimes not very strong concrete so that it crumbles very easily. Hollows can be a problem when you bring your car in from the rain as water will tend to puddle and provide a perfect breeding spot for mosquitoes if you live in hot and humid regions or slippery ice sheets if you live in colder regions.

What about a new concrete floor?

Sometimes if your garage is particularly old or if the quality of the original build was not very good, you might find that there is no option but to pour a new concrete floor. The actual procedure of doing this will vary depending on:

- The thickness of concrete required

- How bad the original concrete is

- Whether you want the new floor insulated and damp-proofed

The only way to get an idea of this is to call a professional and ask his opinion.

You may be able to lay concrete directly on top of the existing floor.

You may just have to break up the existing concrete and use that as a base for the new.

You may have to remove the existing concrete completely and add insulation and a damp-proof membrane before pouring the new floor.

Those choices are for you and a contractor to make depending on your personal preferences and circumstances. Suffice it to say that if you have a new concrete floor poured you can have a polished surface by having a polymer and cement mix added by hand after the concrete has set. This will give a good looking and stable surface which, depending on the proposed use of your garage, may be all you need to finish the surface.

For the remainder of this article let’s pretend that our concrete is in reasonably good condition and will not need replacing. All it requires is a few repairs and a protective surface applied.

How to seal a concrete floor

You actually have quite as the lot of different floor coating options to choose from, the secret is knowing exactly what your requirements are and what your budget will allow. You want a sealing product that is easily affordable but will give you the best value for money. Before you seal the floor, however, you have to prepare the surface to make sure it is scrupulously clean and without any previously applied sealers, paint, moisture, oil or dirt.

If the flooring is not prepared properly then the sealer will not bond completely to the concrete surface and before you know it you will have the coating start to peel off. What a waste of time and money!

Cleaning the garage floor properly and preparing it for a coating uses special tools such as grinders and chemicals such as muriatic acid which, if used carelessly can cause damage to the skin.

Muriatic acid, probably better known as hydrochloric acid can be bought from many home improvement centers but is very toxic and corrosive so there may be age restrictions in purchasing it where you live. When using the acid it is very important that you follow the manufacturer’s instructions very closely and wear the appropriate safety clothing.

Protective gloves. You need to wear latex gloves to protect your skin however because you may be handling rough concrete surfaces you also need gloves that will not easily tear. If you cannot find gloves that incorporate both these properties, there is nothing to stop you wearing surgical latex gloves next to the skin and heavy duty protective gloves over the latex ones.

Safety goggles. You need to be very aware that splashes may cause acid burns in the eyes. These are not only very painful but can cause life-changing injuries such as blindness and scarring. Ordinary safety glasses are not suitable unless they are wraparound and acid proof. The recommendation is to use acid-resistant goggles every time.

Shoes. You will be walking around on a floor covered in hydrochloric acid so you need to wear shoes or boots with acid resistant soles. Most good quality industrial safety shoes or boots are acid resistant but check the specifications before you buy.

Acid resistant clothing. It is no use covering up your skin to prevent acid burns if the fabric isn’t resistant to acid. Hydrochloric acid will burn through most normal fabrics until it reaches your skin. Then it will start on the skin! Wear one-piece coveralls that are guaranteed as acid proof. If you can find one with a hood then that is even better.

Ventilation. The fumes from hydrochloric acid will burn your lungs and other mucous membranes so it should really be used in a well-ventilated area. If you are using it to clean a garage floor then it may not be possible to ventilate the area enough. Use a face mask that will protect your nostrils and mouth from hydrochloric acid fumes.

Neutralising. Although not specifically a piece of safety clothing, when you are handling hydrochloric acid it is always a good idea to have a supply of sodium bicarbonate (also known as bicarbonate of soda) and a bucket of water or a garden hosepipe handy. In case of spills, you can neutralize the acid by covering it with the sodium bicarbonate and then washing the surface with copious amounts of water. While we are talking about safety with hydrochloric acid, do not mix the chemical with chlorine bleach or potassium permanganate as these reactions will produce toxic chlorine gas.

Now we have got the safety requirements out of the way we can now talk about cleaning your concrete floor with hydrochloric acid, or acid etching as it is known.

Mix together one part acid with three parts of water in a garden watering can with a sprinkler rose on the end of the spout. Make sure this is a cheap plastic can as you won’t be able to water your plants with it afterward so just dispose of it carefully. Professionals realize that the concentration of acid to water may vary depending on the strength of concrete your floor is made from.

They would start with a 5:1 ratio mix rather than a 3:1 concentration and try the mixture on a small patch of floor. If nothing happens then adjust the mix slightly until the floor starts to fizz. Most floors, however, require a 3:1 concentration. You must be careful when mixing acid and water. Acid should always be added to water, not the other way around or else there will be an explosive reaction. When you have the ratio correctly estimated just sprinkle the concrete floor with the diluted acid through the sprinkler rose. When the etching process has finished working, all you do is sprinkle the floor with sodium bicarbonate to neutralize any remaining acid and hose the floor to safely dilute the acid and wash it away. You can use a mop to remove excess water.

Safer alternatives

There are safer alternatives than the hydrochloric acid solution. One product is a gel-based hydrochloric acid. One brand name for this is Tek Gel for Profiling (TGP). It is a much easier product to use and can be applied directly to the concrete surface without mixing with water. Always follow the manufacturer’s instructions. After you have applied the gel, scrub the floor lightly using a stiff bristle broom and let it stand for about fifteen minutes. There is no need to neutralize the floor and you can just hose it off.

Tek Gel is also very popular because there is little oil residue left after the cleaning process. Using hydrochloric acid will loosen the oil and grease but won’t absorb it. This product costs more than the liquid version but it provides a better cleaning experience and gives a more consistent etch.

Another safe alternative is to use Eco-Etch Pro. This is a plant-based biodegradable product. Unlike hydrochloric acid it is:

- Environmentally friendly

- Non-corrosive

- Does not harm skin

- No toxic fumes

- Easily neutralized with water

Because of its lack of toxic fumes, it is quite safe to use indoors as well as outdoors. The product is a combination of organic minerals, surfactants, and plant extracts but is still quite an efficient etching agent. It is used at varying concentrations with water depending on the proposed floor coating. Read the instructions that come with the product for the full instructions.

No matter which method of etching you use, allow the floor to dry out for a couple of days before you apply the chosen coating.

Types of concrete floor coating

There are basically three different types of floor coating you can use on a garage floor:

Concrete paint

These can be further categorized depending on what they are made from:

- Oil-based paint

- Latex based paint (in the UK this is called an emulsion paint)

- Epoxy. These are categorized into

- Pure epoxy

- Water-based

- Solvent based

- Polyaspartic

The least expensive type is, not surprisingly the concrete paint. It is really only a more hardwearing version of the ordinary household paint used on walls and ceilings. The appearance of the paint may vary depending on whether the paint is oil-based or latex, in which case the oil finish is glossier and more hardwearing than the latex type. It is also more difficult to apply.

Although the price of concrete paint might seem to make it very attractive for finishing a garage floor, it probably isn’t durable enough to withstand the wear and tear of spilled chemicals, dropped metal tools and hot tires.

If you want to use the best combination of durability and appearance you should choose an epoxy coating. They are very popular and are really considered to be one of the best coverings for garage floors as can be seen from the number of professional garages, car showrooms, and warehouses that use it on their floors.

Epoxy coatings will withstand the usual chemicals and oil found in garages and are resistant to wear and tear, scratches and oil stains. The usual thickness of these kinds of coatings, depending on the type you choose can be between 3mm to 10mm. Not only is an epoxy coating hardwearing and resistant to most liquids, it also looks amazing. It isn’t a surprise therefore that the price is substantially higher than paint.

Let’s talk about the three types and see how they compare.

Pure epoxy. This is the strongest and most durable of the three different types. They come as a two-part coating which must be mixed to produce a hard and thick flooring. They are more easily applied by professionals who will have special training to apply the compound and so they are not usually used by those interested in a DIY project. A well applied 100% epoxy coating can last for anything up to twenty years. These qualities ensure that the coating is the most expensive of the three. The typical coating requires more than one coat so the finished installation price of a typical two car garage can be anything from $1000 to $1,800.

Solvent-based epoxy. This type is stronger and more durable than the water based epoxy. Their application requires the use of respirators because of their high Volatile Organic Compound (VOC) content. They are very easy to apply and attract the DIY approach.

Water-based epoxy. This type of coating is the least expensive of the three and is also the least durable, although it still can withstand scratches, knocks, and chemicals. Unlike the 100% epoxy, this type contains about 40% to 60% epoxy. They are thinner, lower viscosity and easier to apply. However, they need regular re-application as eventually they start to show the wear.

Although epoxy floor coverings seem to be the answer to everyone’s prayer, they do have some weaknesses, the main one being resistance to UV light. Eventually, with constant exposure to sunlight, the epoxy covering will start to discolor.

What about the soft flooring?

So far we have talked about concrete floors and their surface coatings. If you remember we also mentioned that garages might be used as a playroom or a gym. For this, we will need a soft yet firm floor covering that is easily removed and stored when you want to turn the room back into a garage.

There are many different types of rubberized floor coverings available commercially but the best types we have found that ticks all the boxes are an interlocking playground or gym tiles. The prices vary depending on the quality and the specifications but the basic design is of square or rectangular rubber mats of thickness ranging from 0.5” to 2.5” depending on the desired application. The edges have an interlocking sequence similar to the interlocking pieces in a jigsaw puzzle.

The number of mats you have will depend on what area you can cover. They also have the advantage that you don’t have to stick to a boring rectangular area, you can fit the mats together however you desire. At the end of the play session or workout, you can easily take the mats apart and stack them in the corner of the garage until the next time.

Factors affecting garage flooring cost

As always with home improvement projects there are quite a few different factors that will affect the cost of your new garage floor.

Age of the floor. How long have you had your garage? If the garage is quite a few years old then the chances are that it will have had many spills of oil and grease, paint, rust, dirt and other marks that probably you don’t even know what they are. Old garage floors will also need repairing as they will probably have cracks and chips and other signs of wear and tear from many years exposure. An old floor will need more repairs and a particularly dirty and stained floor may require more than one try at etching the surface until it is once again clean.

Area of the garage. The size of the garage floor will affect significantly the cost. Not only will it require more etching but will also need more materials and more labor to coat the floor. While this is probably not too much extra when we are talking about concrete paint, the price can increase dramatically when using a 100% epoxy or polyaspartic floor covering.

Choice of covering. With paint being the cheapest to buy and probably the least expensive to apply, no wonder it is used by the average householder. Not only that but it is the only covering that can easily be applied as a DIY project. After painting in order of cost comes:

- Water-based epoxy

- Solvent-based epoxy

- 100% epoxy

- Polyaspartic

DIY or contractor. The choice as to who is going to apply the coating is a significant factor when we are dealing with paint, whereas there is no choice when dealing with the other coatings, all of which need specialist skills and equipment so therefore need a contractor.

Access. Usually, access to garages is not that difficult as they are built so that vehicles can easily get to them. Very often, however, a garage has been converted into a workshop by removing the double door and adding an extra wall. In this case access may be more difficult.

Time of year. Without fail, the factor that either helps or hinders the application of all these coatings and whether the coating is a good finish is the presence or absence of light. Depending on the time of year you may have to keep the garage door closed to prevent exposure to rain, snow, windblown dust or strong sunlight. This will have the knock-on effect of affecting the quality of the finished product as well as the speed and ease of application.

Availability of contractor. Forget for the moment about applying paint as most general, contractors, decorators or handymen can do that. Consider for the moment the availability of specialist contractors when and if you live in a remote rural area. The nearest contractor may be many hundreds of miles away. The travel time and accommodation for the installation team will be a large factor in the quoted price you receive.

Garage flooring cost

The costs shown in the following tables are indicative only and will vary depending on where you purchase them.

| Typical cost of etching agent | |

|---|---|

| Tek Gel (acid etching gel) | $80 per gallon |

| Eco-Etch Pro (Non-corrosive etching agent) | $30 per gallon |

| Muriatic acid (hydrochloric acid) | $15 per 1 gallon |

| Acid neutralising agent | $50 per 1.5 gallon container |

| Costs of concrete and surface sealant | |

|---|---|

| New concrete floor | $30 per square foot |

| Concrete paint | $0.15 per square foot |

| 100% epoxy coating | $45 to $150 per gallon |

| Water based epoxy | $30 to $50 per gallon |

| Solvent based epoxy | $45 per gallon |

| Installation of all types of epoxy | $1.50 per coat per square foot which can work out at $3 to $6 per square foot |

| Polyaspartic coating | $5 to $7 per square foot with less coats than epoxy |

| Cost of rubberised flooring mats | |

|---|---|

| 0.75” Soft rubber interlocking gym tiles | $90 per pack of 6 |

| 0.5” Interlocking foam floor mats | $20 per pack of 4 tiles (16 sq ft) |

| 0.5” Heavy duty rubber gym flooring rolls | $150 per 4ft x 10ft roll |

| 0.5” Heavy duty rubber gym interlocking flooring tiles | $75 per 4ftx4ft tile (each) |

Safety

All the substances used to clean up and etch existing concrete as well as provide you with a new hardwearing sealed surface can potentially cause harm to you and your family. Following a few simple safety rules will ensure you stay safe and are here to enjoy your new floor.

Acid resistant gloves. Protect your skin from the harmful effects of hydrochloric acid by wearing latex gloves or other suitable material.

Hardwearing gloves. When dealing with concrete, concrete grinders and other abrasive materials, protect your hands with thick leather work gloves.

Chemical resistant goggles. Acids and alkalis can cause severe burns to the eyes and cause blindness as well as scarring. Wear goggles that are resistant to hydrochloric acid and sodium bicarbonate.

Facemask. Acid splashed into your nose and mouth is very painful and can cause severe scarring. Wear a protective mask to protect against splashes.

Ventilation. Acid fumes and VOCs are toxic when inhaled. Ventilate the work area as much as possible. If you cannot do this then wear a respirator designed for these fumes.

Safety boots. Acid on the floor will soon corrode your shoes. Make sure you wear shoes or boots with acid resistant soles.

Protective coveralls. The splashed acid will eat away at your clothes and then start on your skin. Wear acid resistant coveralls to protect your ordinary clothes and your body.

Conclusion

There is no doubt about it that having a good quality garage floor that withstands oil and chemical spills together with wear and tear from hot tires and dropped tools is a necessity for anyone who spends a lot of time tinkering with their car. The protective surface doesn’t have to be too expensive either. If your budget is tight, you don’t mind doing the work yourself and are prepared to give the floor an additional coat every year or so then there are many good quality concrete paints that are available. If however money is no option then you have a choice of anyone from a range of epoxy type finishes or the new polyaspartic finish that has all the benefits of epoxy with not many disadvantages (except the price).

Once you have a nice shiny new garage floor you will find that all the family will want to get in on the act too. Your partner will want to use it for a workout session and the children will want to play there when it is cold and wet outside. It is then that you purchase some hard wearing interlocking rubberized mats that can be spread out on the floor and be stored away tidily in a few minutes.

With a little bit of planning and money, you can make a dirty, oily and smelly garage that has only been used to store old bikes and half-empty paint cans into a pleasant workroom just right for hobbies, play and parking the car.

We would like to thank you for reading.